The Lindsay’s Door Difference

12-Step Finishing Process

Our commitment to this process keeps the finishes consistent and the quality high.

Includes:

4-Step sanding process

Full door inspection

Safe packaging and transport

Full disassembly and reassembly

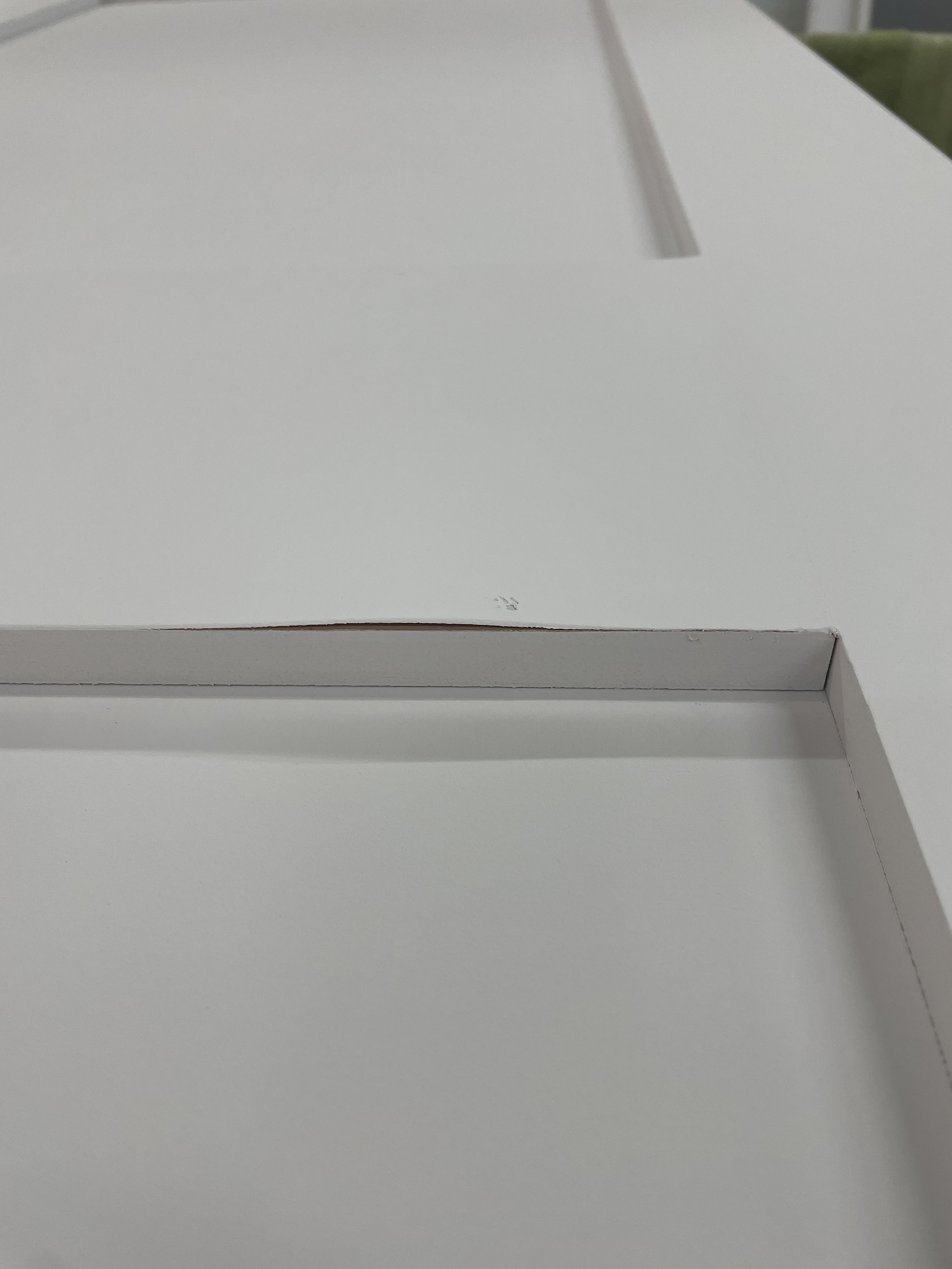

Full Coverage

Our finishing techniques ensure all the hard-to-reach areas of a door are finished.

Finish all 6 sides of a door to prevent moisture penetration and warping

Door and frames are disassembled and finished separately

Doors are coated in horizontal position for full coverage without worry of runs.

Sprayed - Not Brushed

Doors are sprayed with professional equipment in a controlled environment

No brush marks or roller laps

Coating is uniform when sprayed all at once

Our Process

Preparation: The best results begin with detailed preparation. Don’t let your painter or finisher skimp on the SANDING. Our hand sanding process is necessary to remove shavings, smooth profiled edges, and removing any milling glaze. It also gives us the chance to catch imperfections like milling marks or excess glue on the wood prior to staining. Our prep process is what leaves you running your hands across the finish wondering how can this be so smooth.

Coatings: For painted millwork, coatings always include a wood primer and topcoat(s). For stained millwork, we apply stains in a number of ways always finishing with a brush followed by an industrial grade sealer and topcoat(s). The standard application is two to three coats to reach the desired mil thickness. This gives you the confidence that what you are paying for will stand the test of time.

Care and Handling: We have developed handling techniques and use drying racks that prevent any contact with finished material until it is fully cured. The packaging, loading, and transport of the finished millwork is all done in a time-tested manner that guarantees a factory finish delivered to the project site.

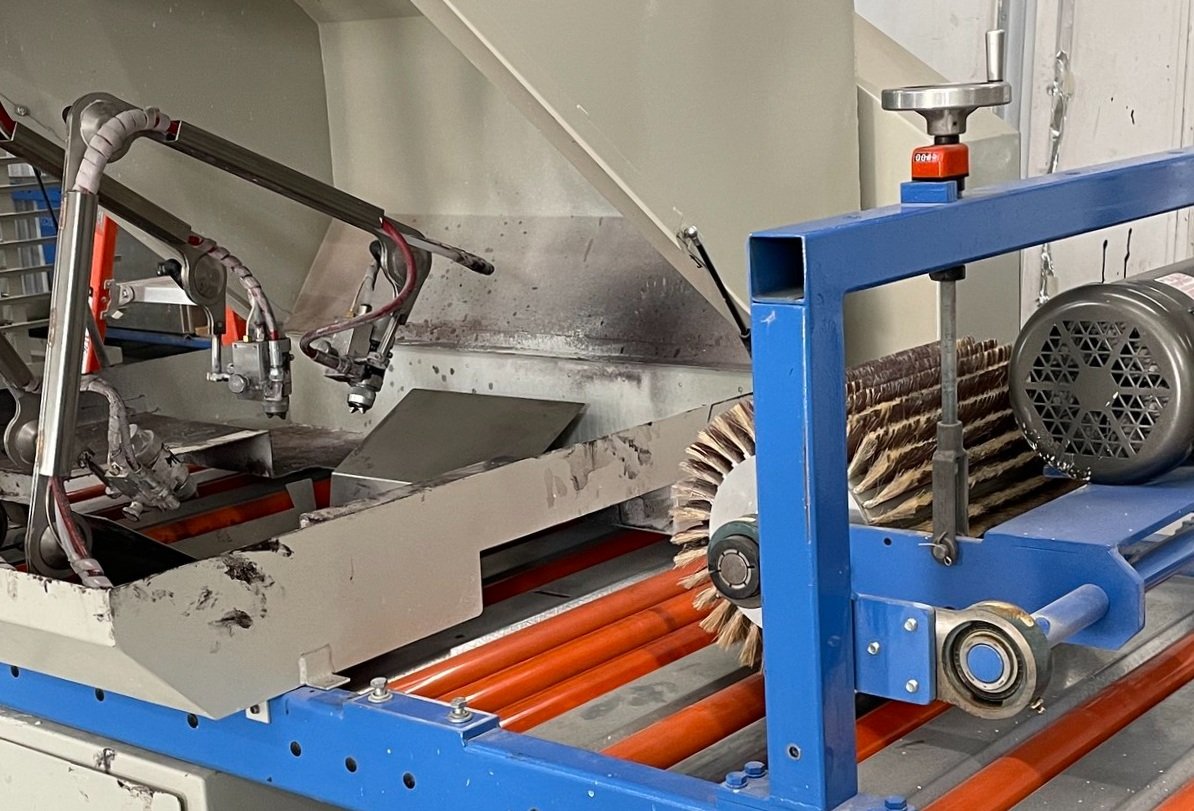

Our Technology

Finishing Equipment: The right product and proper preparation are fundamental to a quality finish, but you also need the right equipment. We use finishing equipment selected from the industry’s most reputable companies. This equipment gives you a smooth, consistent finish that is unachievable on your own or on a jobsite.

Controlled Environment: A controlled finishing environment is more than just a building. Our facility contains a ventilated spray booth for safe spraying and a dust control system for a dust-free environment. This environment along with a conditioned space allows for uniform color, sheen, and proper drying conditions.

Automated Finishing Line: While our custom processes mean that no project is too small, our automated finishing line means that no project is too big. For projects with large quantities of linear millwork, our automated finishing equipment helps deliver quality results on schedule. In almost all manners, the benefits of prefinishing millwork for a customer increase as the volume of millwork increases, and we are here to service your needs no matter how big or small.

Our Products

Stains: We use a number of different stain types and brands depending on the material to be finished. To get the desired look, staining can include a number of different products or approaches from custom mixing, layering of stains, or adding dyes to achieve the right look. Rely on our expert understanding of how to select and apply stains to tie your project together.

Clear Coats:

Sealer: When finishing with clear coats, we apply a non-yellowing, industrial-grade sanding sealer as the first coat. Sanding sealers are excellent for increased moisture resistance, while allowing for easy sanding to a ultra-smooth surface prior to applying any topcoats.

Topcoat: There are a number of topcoat options available : water-based, solvent-based, and oil-based are the general categories. We use finishes from each category in our processes and each is selected for increased performance for each specific application. Take advantage of our access to the top products on the market for your project.

Paints: We apply the highest end water-based products to our painted millwork. The performance of water-based paints has come a long way over the past decade. For interior applications, we use a cross-linking enamel paint that both dries hard and touches-up well on the jobsite. For exterior applications, we apply a mildew-resistant acrylic paint. Let us show you how the best paints available will outperform the hardware store paints.